Pad eye plates are one of the smallest and most commonly used structural items in the marine and oil and gas industries. They are also used for a variety of purposes: from simple offshore securing of cargo to the ship's deck, to complex lifting operations involving multiple lifting points. Despite their seeming simplicity, the geometry of eye pads can vary greatly depending on their use. When they are used for lifting purposes, they are also referred to as lugs.

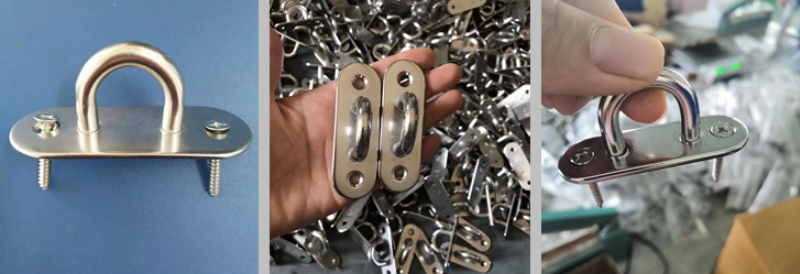

Stainless Steel Oblong Pad Eye Plate

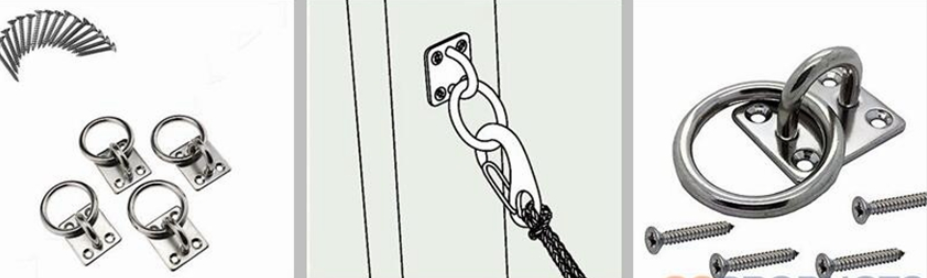

The basic purpose of the eye pad is to provide a point to which the rope or wire can be secured, either directly or through a release buckle. The other end of the rope/wire can be secured to another pad eye elsewhere, or it can be used for lifting.

The most common use of a pad eye on a ship is to secure cargo to the deck of the ship. The most common way we can secure cargo to the deck is to use ropes or wires to tie it to the deck. The question arises - to which point on the deck do we tie it? What should the attachment point look like? Thinking in very basic terms, the attachment point should have a slot through which the rope/wire can pass. In addition, the attachment point should be welded to the deck.

The dimensional variation of the bedding eye is very obvious. Operations that apply higher loads to the pad eye will require a larger size pad eye. For example, using a single point lift to lift a 1 ton load will result in a much smaller pad eye size than if a 10 ton load is used.

The shape of the pad eye may vary depending on the application. When only vertical loads are expected to be present on the pad eye (for example, lifting operations where the lifting sling is completely vertical), the pad eye is usually symmetrical in design. Symmetrical pad eyes can also be used for sling angles of 60 degrees from the horizontal/bottom of the pad eye. However, if a sling angle of less than 60 degrees to the bottom of the eye is expected, it is recommended that an asymmetrical eye be used.

We can see that the pad-eye has three distinguishing features.

1. the main board - this is the asymmetric board with the eyelet through which the rope passes.

2. pad-eye hole - this is the slot through which the wire/rope passes. The size of the hole depends on the size of the rope that must pass through it. 3.

3. Cheek plates - Not a required feature, these are round plates that are welded to the main plate to reinforce the main plate around the hole. The area of maximum stress is around the hole, so the cheek plates are only used to reinforce that area and save material that would otherwise be wasted on a thicker main plate. Pad eyes can also be made without cheek plates, they may also have two cheek plates on both sides.

The bottom of the pad eye is usually welded to the item to be tied down. It can be the deck of the ship or the cargo.

Stainless Steel Square Eye Plate with Ring

While eye pads may appear small, their design involves multiple checks and complexities that depend on the geometry and use of the eye pad. Whether designing a new eye pad from scratch or evaluating the suitability of an existing pad for a particular operation, these factors need to be carefully considered to ensure a successful procedure.

Looking for help in designing or selecting the right eye pad for your operation? Please contact us for custom services. HAIFAN is a professional manufacturer of rigging, release clips, and cable assemblies, and we look forward to your inquiry.

Happy Women's Day

Happy Women's Day

New Laser Cutting Machine

New Laser Cutting Machine