The purpose of the thimble is to highlight and support the eye formed by winding the outside of the wire rope. The thimble forms a durable, wear-resistant surface and helps support the wire rope eye. They are just one of many types of wire rope accessories (collars, wire rope clips, terminals, etc.) HAIFAN introduces you to its material selection and installation method.

Wire rope sleeves are available in a variety of strengths and materials, but there are two main different working grades

Light Duty: Our light duty thimbles are all galvanized and can be used for static applications.

Heavy Duty: Heavy duty rope sleeves are hot dipped galvanized to produce a thicker coating.

Choose our stainless steel wire rope thimbles if you are using it in high humidity or corrosive environments. Stainless steel thimble is also ideal for use in or near salt water environments where corrosion often occurs, making it the best choice for harsh environments.

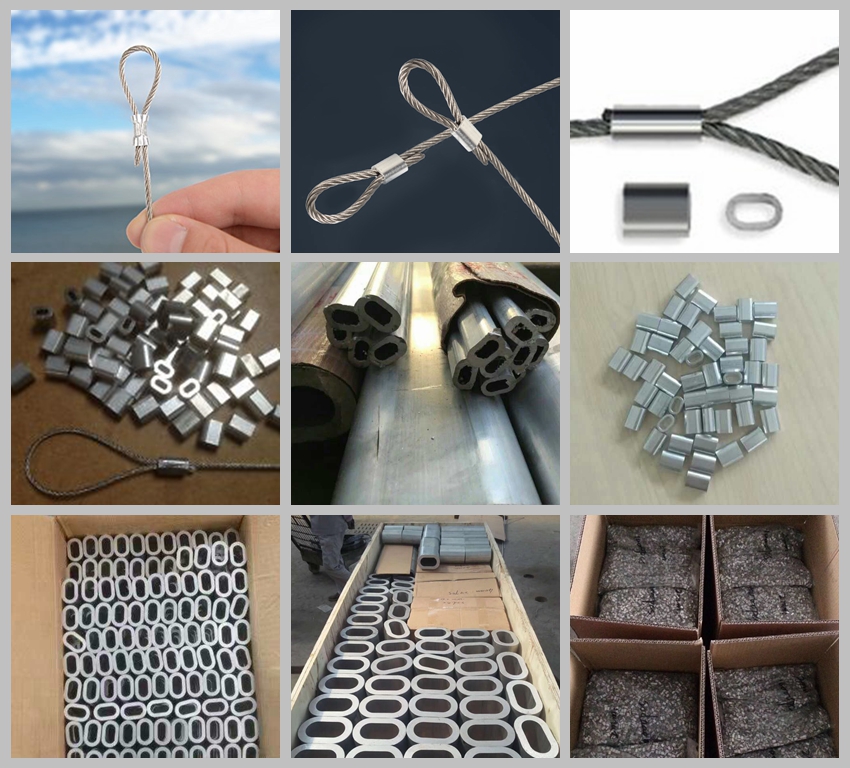

Stainless Steel Wire Rope Tube Thimble

Our heavy-duty, hot-dipped galvanized thimbles are less costly than stainless steel and are also suitable for outdoor environments. While galvanized parts are also ideal for outdoor use, galvanized parts may show signs of surface rust if the galvanized coating wears off in the load-bearing or contact areas of the part.

Thimbles can be used in conjunction with cables and ropes to form rigging assemblies. The most important thing to consider when doing so is to ensure that the thimble is correctly sized and securely fastened in the eye of the cable being used.

Thimbles are often used with other rigging assemblies that have strong eyes and must be open to do so. You can use a set of pliers to hold each side of the thimble and open it with a twisting motion in order to insert the assembly into the thimble and then return the thimble to its normal shape.

Wrap the end of the wire rope around the outer groove of the thimble and tie the dead end of the rope to the U-bolt or wire rope collar crimp of the wire rope clamp. Secure the thimble to prevent friction-induced wear.

Once in place, place the other wire rope clamp near the loop just wrapped around the thimble. Tighten the nut, but not yet to the proper torque, we recommend using a crimp/type forging tool to firmly press the collar onto the rope to secure your ejector ring firmly.

Apply all other wire rope clamps, spaced equally between the first two, and tighten them securely to the recommended torque using an adjustable wrench. They should be 6-7 rope diameters apart.

Make sure that the cable sleeves are correctly sized and securely fastened in the eyelets, not too loose or too tight, so that they form an additional support layer for attachment to other properly sized rigging accessories.

Hafan Rigging can provide a variety of sizes of rope sleeves to accommodate a wide range of rope/cable diameters. It is important to select the right size thimbles, so please contact us to discuss your requirements and place your order today. We also offer a wide range of replacement wire rope fittings to suit a variety of applications.

Happy Women's Day

Happy Women's Day

New Laser Cutting Machine

New Laser Cutting Machine