Whether you are a hiking enthusiast, a pet owner, or a colleague in the construction industry, you have certainly used wire rope clips and screw turnbuckles. Rope clips are a common and necessary piece of rigging hardware. They are used to form rope eyes or to join two cables together. Here, the wire rope clamp manufacturer shares how to use wire rope clamps and avoid some common mistakes.

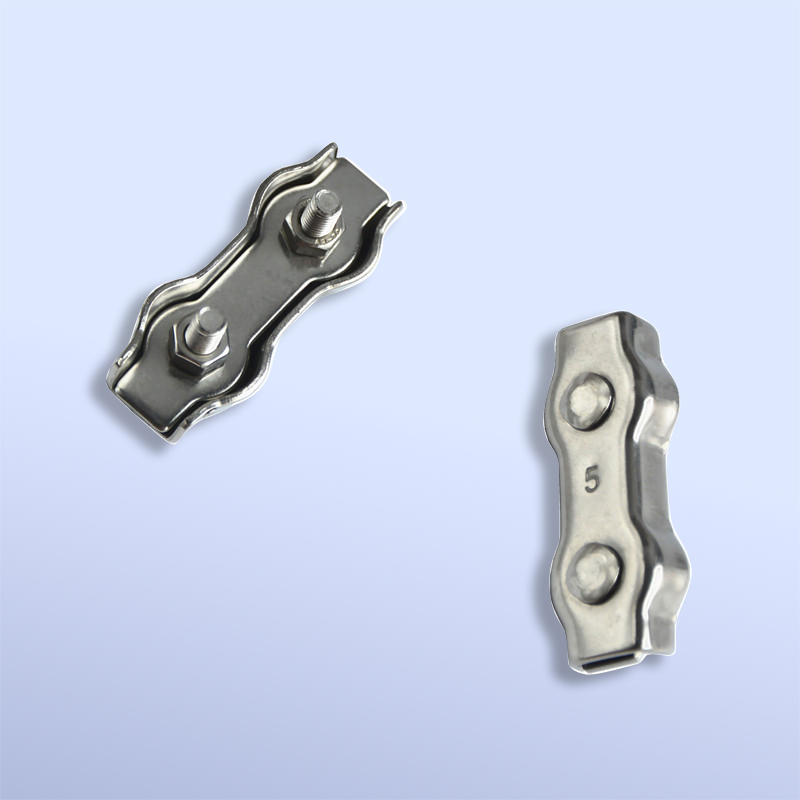

Duplex Wire Rope Clip

Unfortunately, it is not uncommon for wire rope clips to be applied incorrectly. Here are some mistakes to avoid.

The use associated with wire rope diameter requires a minimum number of clips. Using less than the specified number of clips may result in reduced efficiency and possible failure.

Wire rope clamps require the use of a torque wrench to work properly. Over or under tightening the nut on the clamp can cause the clamp to fail. If the clamp is over-torqued, the wire rope threads may be damaged. If the clip is under-torqued, the holding power of the clip will be weakened and the wire rope may slip through.

It is important to ensure that the correct type of wire rope clip (forged or extensible clip) is used for the application. Extendable clips should only be used for non-critical applications, such as tension ropes used to form a perimeter around a parking lot.

If the use is critical - where you could suffer injury or loss of life or property damage if a failure occurs - forged clips must be used.

Jaw and Swageless Turnbuckle

The foldback is the portion of the wire rope eye that extends from the bearing eye end to the charged end. Less than the recommended amount of foldback will reduce the efficiency of the wire rope eye and may lead to failure.

Depending on the number and size of the wire rope clips, a certain percentage of space is required between the placement on each clip on the wire rope.

The clamp size used - whether 1/8", 3" or other - must match the diameter size of the wire rope. Otherwise, the rope may slip out of the clamp.

Once the clamp is installed, the rope needs to be cycled and the clamp retightened periodically. It is important to monitor the torque on the nuts, as they can loosen with repeated use.

It is important to know how to properly install wire rope clamps, as incorrect installation can result in a less efficient wire rope assembly. If interested, please contact us, we offer closed rigging screw fasteners, stainless steel hooks, wire rope clips and open body screw fasteners, etc.

Happy Women's Day

Happy Women's Day

New Laser Cutting Machine

New Laser Cutting Machine